Choosing the right rubberising equipment is crucial for delivering high-quality results and ensuring the longevity of your services. Whether you are starting a new business or expanding your current offerings, here’s a comprehensive guide to help you select the best rubberising machines and tools.

1. Understand Your Business Needs

Before diving into equipment options, it’s essential to assess your specific business needs. Are you primarily focusing on automotive applications like truck beds and commercial vehicles, or are you targeting industrial and residential projects such as flooring and containers? Identifying your primary services will guide your equipment choices.

2. Key Equipment Components

Rubberising Machines

The core of your setup, rubberising machines, come in various models tailored to different scales of operation. Look for machines that offer:

- Durability: Ensure the machine can withstand heavy usage.

- Efficiency: Higher throughput machines can save time and labor.

- Ease of Use: User-friendly interfaces and easy maintenance are critical.

Spray Guns

Spray guns are vital for applying rubber coatings evenly. Consider the following when selecting spray guns:

- Precision: High-precision guns provide better control over the application.

- Compatibility: Ensure compatibility with your rubberising machine.

- Adjustability: Adjustable spray patterns can be useful for various applications.

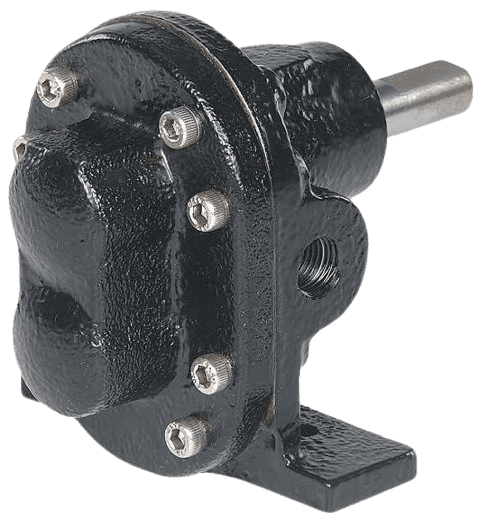

Pumps

Pumps play a crucial role in the delivery of the rubberising material. Look for:

- Reliability: Pumps should have a reputation for long-term performance without frequent breakdowns.

- Capacity: Choose a pump that matches your expected workload.

- Maintenance: Opt for pumps that are easy to service and maintain.

3. Balance Cost and Value

Investing in rubberising equipment involves balancing upfront costs with long-term value. While it might be tempting to go for cheaper options, investing in high-quality, durable equipment can save money in the long run due to reduced downtime and maintenance costs.

4. Supplier Reputation and Support

Partnering with reputable suppliers is crucial. Look for suppliers who offer:

- Excellent Customer Service: Responsive support can save you time and hassle.

- Training Programs: Free training on how to use and maintain the equipment is a significant plus.

- Warranty and After-Sales Support: Comprehensive warranties and reliable after-sales support are essential for peace of mind.

5. Review and Test Equipment

Before finalizing your purchase, review product specifications, read customer reviews, and, if possible, test the equipment. This hands-on experience can provide valuable insights into the equipment’s performance and suitability for your business.

Conclusion

Choosing the right rubberising equipment is a strategic decision that impacts your business’s efficiency and service quality. By considering your business needs, evaluating key equipment components, balancing cost and value, and partnering with reputable suppliers, you can ensure you select the best tools for your operation.